vickers hardness test vs brinell|difference between vickers and rockwell : member club Brinell hardness testing is best for large and rough materials, and when a representative average hardness value is needed. Rockwell hardness testing is versatile, offers different scales, and is suitable for various materials, .

- instagram: @shesusandventing - snapchat: @susandventing - tiktok: @shesnotsusandventing - twitter: @notaeshannah

{plog:ftitle_list}

webFazenda Churrascada Curitiba em Curitiba, consulte o Cardápio e menu original, descubra os preços, leia as avaliações dos clientes. O restaurante Fazenda .

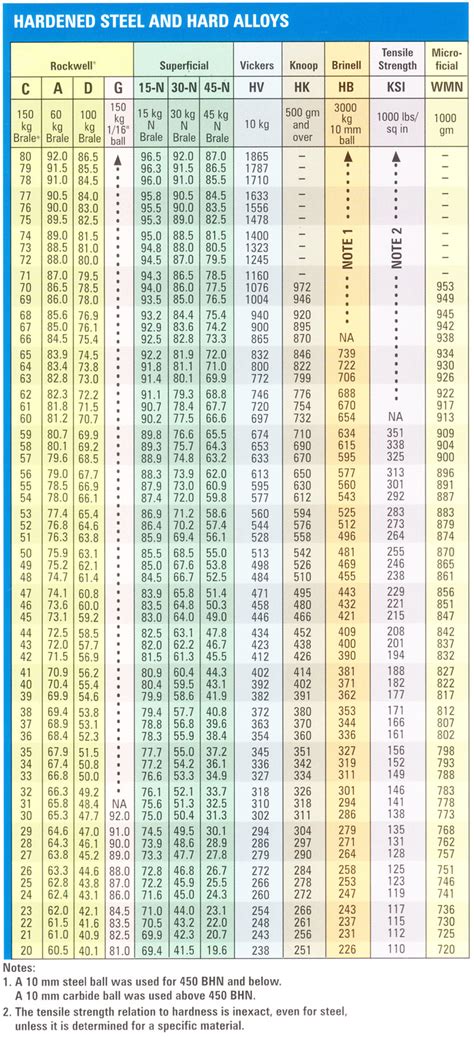

There are three principal standard test methods for expressing the relationship between hardness and the size of the impression, these being Brinell, . This table shows approximate hardness of steel using Brinell, Rockwell B and C .Understanding the Vickers and Brinell Hardness Tests. Before diving into conversions, it’s essential to understand how the Vickers and Brinell hardness tests work. 1. Vickers . The three most well known and widely used hardness tests for metals today are Brinell, Rockwell, and Vickers. Here are the basic differences explained.

Making use of a diamond indenter, the Vickers hardness test is done with less force and more accuracy than the Brinell test. By magnifying the surface of a metal, this test can target specific microstructural constituents like .

Brinell hardness testing is best for large and rough materials, and when a representative average hardness value is needed. Rockwell hardness testing is versatile, offers different scales, and is suitable for various materials, . Dozens of different hardness tests find use today, including Brinell, Rockwell and Vickers. Each has variants based on the load used to create the indentation. Brinell tests use the largest loads, suiting it for testing thicker test .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

Understanding the Vickers and Brinell Hardness Tests. Before diving into conversions, it’s essential to understand how the Vickers and Brinell hardness tests work. 1. Vickers Hardness Test. The Vickers test uses a diamond pyramid-shaped indenter that presses into the material under a specific load.

Standardized optical hardness testing methods include the Brinell hardness test (ISO 6506, ASTM E10), Knoop hardness test (ISO 4545, ASTM E92, . Hardness test methods in the macro range include Brinell, Vickers and .The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. . The test forces used in the macro range in the Vickers method are mostly substantially smaller than those used in the Brinell method. The preferred choice for the macro range is 49, 98, 196, 294, 490 or 980 N, with .The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method , which is mostly used for small parts, thin sections, or case depth work. Because the indentation ball is so much larger than in other testing methods, hardness values derived from the test provide a more representative average hardness of the part. More information about Brinell testing can be found in ASTM E10.

Vickers hardness test; Rockwell hardness test; Specially prepared specimens or real components can be used for hardness testing, provided that their functionality is not impaired due to the indentation left behind. . The Brinell hardness test is not suitable for very hard materials or hardened surface layers because the ball does not . The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. . Brinell Hardness numbers in parentheses are outsite the range (HB>630 .The Vickers hardness test is more accurate than the Rockwell hardness test because of the use of a microscope to measure the indentation. . 2012 are two examples of such regulations. These standards’ conversions, which incorporate the Vickers, Brinell, Rockwell B, and Rockwell C hardness scales and conversions for a select few material .Brinell Hardness The Vickers hardness test utilizes a pyramidal diamond in-denter to create an indentation on the material‘s surface. The diagonals (x and y axis) of the indentation are measured, and the hardness value is calculated based on the applied load and the indentation size. Vickers belongs to the optical methods. Vickers Hardness

Brinell and Rockwell Hardness Conversion Chart - These Conversion Tables presents data in the Rockwell A, B, C, D, E and F hardness range on the relationship among .

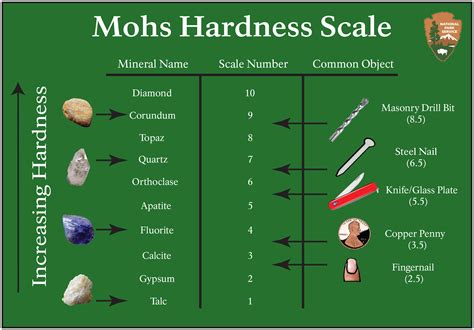

vickers hardness to mohs scale

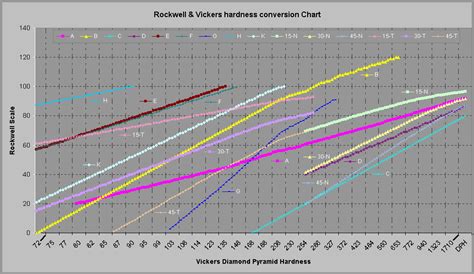

rockwell hardness scale comparison chart

Brinell hardness test is slower to perform with the estimated time of 30 to 60 seconds, while Rockwell hardness is fast enough to show results in 10-15 seconds. . Why is the Rockwell test better than Brinell or Vickers? Rockwell hardness testing method is the most affordable, easy, and quick process than any other test like Brinell or Vicker. .

What is Brinell Hardness Test? The Brinell hardness test is the method measuring hardness through measuring the diameter of the indentation left by an indenter or other materials of a specified diameter, under a certain load into the surface. The Rockwell method is the most commonly used and versatile hardness test.

ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for measuring the Brinell hardness of metals. ISO 6507: This standard contains the details for the Vickers hardness test in metallic materials.

On metallic materials from very low to very high hardness, the Vickers hardness test is applicable. This hardness test is particularly suitable for very small and very hard samples. . The hardness test according to Brinell is for metallic .

We explore the Difference Between Vickers and Knoop hardness test ,and when each test is best suited for specific applications. 713-827-0700 . [email protected] . REQUEST QUOTE . Search input . Ametek Portable . The Brinell hardness test involves pressing a small metal ball into the surface of the test material with a known amount of force. The resulting indentation is then measured and converted into a hardness number. Brinell hardness of some materials. . Others include the Rockwell hardness test and the Vickers hardness test. Calculating Brinell .The Brinell hardness test (HBW) serves as a crucial scale for quantifying material hardness, defined in ASTM E10 and BS EN ISO 6506-1 standards. . ASTM E140 gives tables for conversions between the two hardness types and material types along with others such as Vickers and Knoop. It is also important to note that all hardness conversions are .Hardness knowledge. Comparison between Knoop and Vickers methods. . With an identical test load, the Knoop diamond indenter penetrates the specimen only half as deep as the Vickers diamond indenter. . the Knoop method is best suited for use with small, longish test specimens, whilst the Vickers method is better for small, rounded specimens .

This Vickers hardness number calculator uses the size of indentation to return the hardness of the material. There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and Vickers hardness test.. The Vickers hardness scale, named after the company where it was developed in 1921, is the focus of this article. With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness. Vickers hardness te.

The Brinell hardness test measures material hardness by determining the diameter of an indentation made by a hardened steel or carbide ball under a specific load. A load, typically ranging from 500 to 3,000 kgf, is applied to the material’s surface for 10-15 seconds, allowing the ball to penetrate and create an indentation. The Vickers hardness test, developed by George E. Sandland and Robert L. Smith, is a microhardness test commonly used for thin materials or small regions of a sample. . In conclusion, Brinell, Rockwell, and Vickers hardness tests are valuable methods for evaluating the hardness of different materials. Each method has its advantages and is . Our hardness conversion calculator enables you to convert steel hardness from one scale to another.You're not the first to wish for an accurate conversion from Brinell hardness number to Rockwell or Vickers scale and vice versa. But for the reasons we'll get to in the following article, this conversion is only approximate!. Below, we shall briefly look at the three .

The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, and Scleroscope Hardness1 . both the Rockwell and Brinell hardness standards (Test Method E 18 and E 10, respectively) allow or require the use of tungsten carbide ball indenters; however, all of the ball scale Rockwell hardness .The Brinell, Vickers & Rockwell tests–Brinell test indenter is made of hardened steel. Vickers test indenter is made of diamond. Find out more at UNSW. . Brinell testing is not suitable for very hard materials since the hardness of the test material approaches that of the steel indentor. As a result there will be a tendency for the indentor .

rockwell hardness comparison chart

difference between vickers and rockwell

A Resultado Fácil possui os melhores Palpites do Jogo do Bi.

vickers hardness test vs brinell|difference between vickers and rockwell